The Perforcam optical-electronic navigation system is used for all pilot control operations. It consists of optical target, a camera, a monitor, and a number of supply cables. First of all, the direction and tilt of the camera and the thrust boring unit is set according to the project requirements. The pilot operation is controlled by viewing the position of the target (inside the steering head) using the camera and displaying live pictures on the monitor.

Using the pilot rods, steering head and the Perforcam optical-electronic navigation system you can complete your pilot bores with pinpoint accuracy. Depending on the ground conditions encountered on site you should always use double wall pilot rods to ensure use of BMA pump & tank mixing systems, along with various aggressions of steering head.

The bentonite mixing systems are used both to reduce surface friction whilst creating the pilot bore and also when using the tow back method by attaching a reamer and towing head to end of pilot rods and pulling back the product pipe.

They are equipped with a tank, a mixing unit and a pumping station. The systems are driven either by an on board diesel driven power pack that provides hydraulic power or by connecting to the hydraulic power pack supplied with the PBA machine.

We hold an extensive range of casings and augers that are suitable for the installation of a varied diameter of product pipes. These casings and augers cover sizes from 219mm to 1016mm diameter.

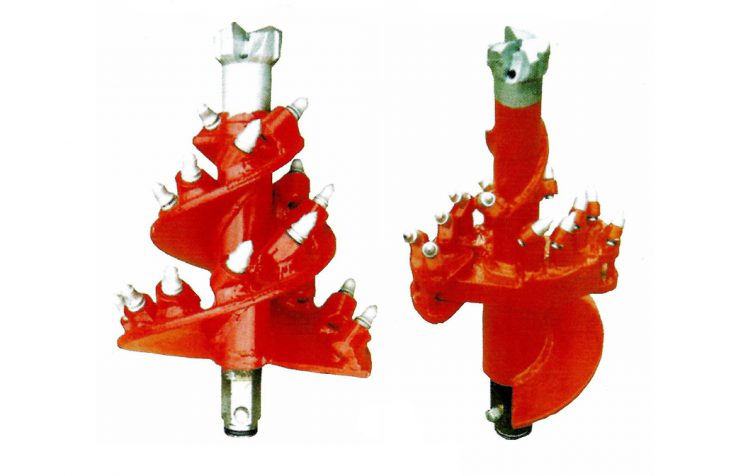

The cutting heads are designed to remove the ground at the cutting face.

The type of head to be used will depend on the ground condition in question, the technique being used and the diameter of the pipe to be installed.